Comparing Carbon steel vs Stainless steel may seem rather redundant at first, as all steel contains carbon. However, they are two very distinct classes of steel, each with distinct properties and, therefore, unique applications.

Steel is a commonly misunderstood material. The term actually refers to a whole range of metal alloys with hundreds, even thousands, of different grades and types.

All steel is made from the same two fundamental ingredients: iron and carbon. From here, various alloying elements like chromium, manganese, nickel or silicon are then added in specific amounts in order to obtain specific physical properties.

With over 3,500 different steel grades, keeping up with them all can be confusing. So instead, steel is typically categorised into four main types: Carbon, Stainless, Alloy and Tool steel.

Let’s take a closer look at Carbon and Stainless steel, comparing their compositions, properties, and applications, helping you understand the vast and complex world of steel to choose the most suitable grade for your next project.

Carbon Steel

Carbon steel is exactly what it sounds like. It is a carbon-iron alloy, often described as a low-alloy steel due to the low levels of alloying elements it contains. It’s defined by its carbon content, with a typical range of between 0.12% to 2.5% carbon in its chemical composition.

Carbon steel is commonly on the cheaper side of the steel spectrum as it’s much easier to produce than its high-alloy alternatives, making it a popular choice for a number of uses.

Carbon steel can be broken down further into two separate categories of high carbon and low carbon, referring to the percentage of carbon it contains. Even though the amount of carbon differs in the small range of 0.12% to 2.5%, the resulting physical attributes of each vary significantly.

High carbon steels have higher Hardness values, making them great at keeping their shape under pressure and resisting abrasion. However, a higher hardness value places the high carbon steels at risk of cracking under stress as they are incredibly brittle.

On the other hand, low carbon steels subsequently have a lower hardness value but are more ductile and therefore easier to work with. They are also typically cheaper than steel with a higher carbon content due to fairly low production costs.

Lower carbon steel is much softer, making it easily machinable and ideal for welding, whereas the more rigid high carbon steel can be more challenging to process.

Carbon Steel Composition

The table below shows the chemical composition of one of the most prominent Carbon steel grades – 1095.

| Material | Iron | Carbon | Manganese | Sulphur | Phosphorous |

| 1095 Steel | 98.4% | 0.95% | 0.5% | <0.05% | <0.04% |

Each carbon steel grade will have slightly different amounts of carbon in them, altering the amounts of the rest of the chemicals too.

Carbon Steel Properties

| Type of Carbon Steel | Carbon Content | Properties |

| Low Carbon Steel | 0.25% – 0.60% | Low hardness value, highly ductile, high toughness, great machinability & weldability |

| Medium Carbon Steel | 0.60% – 1.25% | Low hardness value & hardenability, medium strength, average ductility & toughness |

| High Carbon Steel | 1.25% – 2.50% | High hardness value, great strength & toughness, low ductility |

Carbon Steel Applications

Overall, carbon steel is a brilliant all-rounder material. Because of this, it’s used across all industries in a wide range of applications, including:

- Car body parts

- Axles, Gears & Shafts

- Pipes & Couplings

- Fences, Gates & Railings

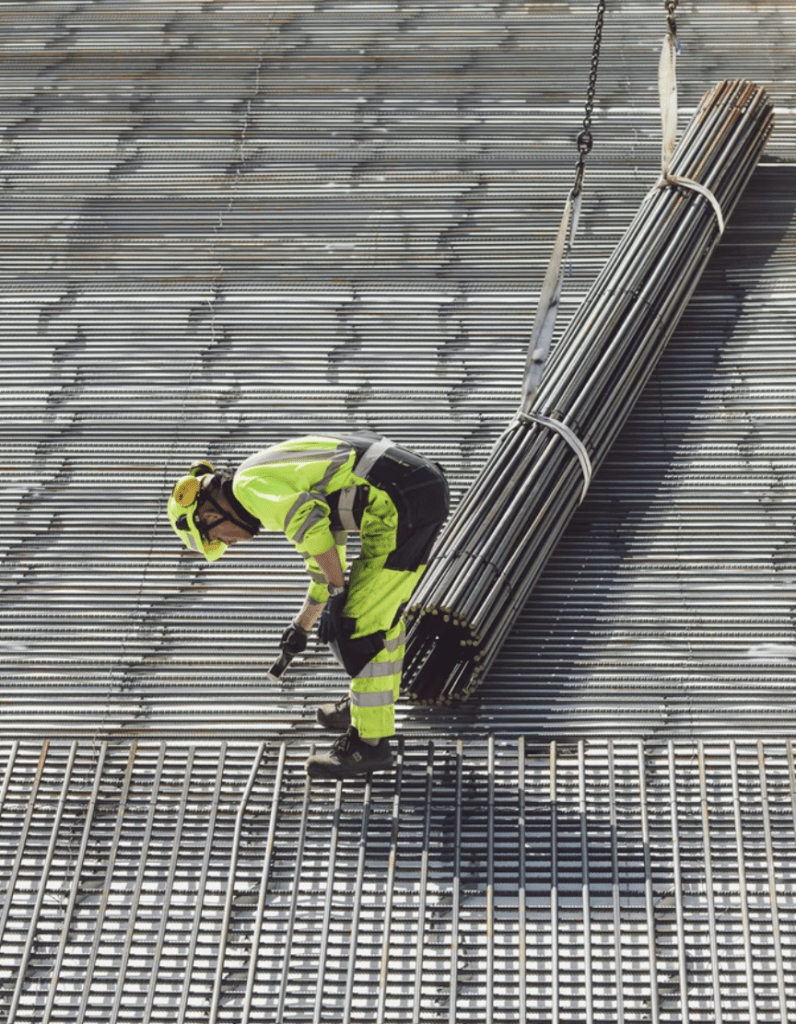

- Construction components

- Food cans

- Home appliances

- Railway tracks

- Cutting Tools

- Guillotine Blades

- Punches

- Dies

- Wire

Contact Sheffield Gauge Plate for more information about the uses of carbon steel and how we can supply the right option for any project.

Stainless Steel

Just like carbon steel, stainless steel is also made from iron and carbon; however, the distinguishing factor is the addition of at least 10.5% chromium. Chromium is the element that gives stainless steel its shiny appearance.

Stainless steel, unlike carbon steel, is highly resistant to corrosion and abrasion. This is because the chromium in its chemical composition reacts with oxygen in the air, resulting in a protective layer that surrounds the material.

Rust occurs when the iron in steel is exposed to oxygen and turns into iron oxide; however, the protective chromium barrier prevents this from occurring. The higher the chromium content, the more corrosion resistant the steel.

Lower percentages of chromium will still be stainless and have some corrosion resistance, although it will be less durable and could still rust over time. However, if your finished product will be out in the elements, it’s well worth paying the extra money for a higher chromium content that will last much longer.

Stainless Steel Composition

The table below shows the chemical composition of the most popular stainless steel type – 304.

| Material | Iron | Carbon | Manganese | Sulphur | Phosphorous | Chromium |

| 304 Steel | 66.5% | 0.08% | 2.00% | 0.03% | 0.045% | 18.0 – 20.0% |

Stainless Steel Properties

- High corrosion resistance

- High toughness value

- Great ductility

- High strength

Stainless Steel Applications

Due to its high resistance to wear and tear, and ability to get wet, stainless steel is used across a wide range of industries for numerous uses, including:

- Exhausts, grills & trims

- Transport & shipping containers

- Surgical & Dental instruments

- Medical machinery

- Replacement joints & pins

- Kitchen & Bathroom equipment

- Aeroplane & Jet engines

- Kitchen utensils, cutlery, pots & pans

Contact Sheffield Gauge Plate for more information about the uses of stainless steel and how we can supply the right product for any project.

Advantages & Disadvantages of Carbon Steel

| Advantages | Disadvantages |

|---|---|

| Wear-resistant | Brittle |

| Highly durable | Tough to work with |

| Environmentally friendly & recyclable | Susceptible to corrosion |

| Affordable | Less polished finish |

| Increased strength | Shorter life expectancy |

Advantages & Disadvantages of Stainless Steel

| Advantages | Disadvantages |

|---|---|

| Highly corrosion resistant | High initial cost |

| Long-lasting | Difficult to work with |

| Highly durable | Often needs re-working |

| Strong & tough | Causes waste |

In conclusion, neither carbon nor stainless steel is better or worse than the other. Instead, they both have unique properties thanks to their varied chemical compositions, making them suitable for different uses. When deciding which steel type to go for, it’s vital to first assess the requirements necessary for the finished product.

Carefully consider how long you need it to last, will it be outside in the elements, does it need to be malleable or will it be under regular pressure, etc. Once you’ve got your list of requirements you can then make an informed decision on whether carbon steel or stainless steel is the most suitable.

Here, at Sheffield Gauge Plate, we stock a wide range of steel grades in various forms, including ground flat stock, tool steel, high-speed steel and machine knives.

If you have questions on which steel type is most suitable for you, contact our friendly team today on (+44)114 233 5291, email us at sales@sgpltd.co.uk or use the live chat feature for advice.