Choosing the correct material for your blades can often be a confusing task. Ultimately the answer comes down to the blade’s intended purpose and resulting necessary qualities. This article will look at one of the most common materials, Tungsten, analysing its properties and uses and the overall effectiveness of a Tungsten blade.

What is Tungsten?

Tungsten is the 74th element in the Periodic table. It is one of the strongest metals on Earth, with the highest melting point of all metals – melting at the temperature of 3,422°C!

However, the metal is incredibly dense in its purest form, making it brittle and tough to work with. Despite its impressive properties, the hardness value of Tungsten is surprisingly low at 7.5 on the Mohs scale. This value is similar to that of hardened steel and is soft enough to be cut using only a hacksaw.

Because of this, Tungsten is most commonly used as an alloying material. Combined with other metals to benefit from the physical and chemical properties of each of them. By alloying Tungsten, you still benefit from the heat resistance and overall toughness, yet the alloy is much more useable and suited to a broader range of applications.

What is Tungsten Carbide?

The most common alloy of Tungsten is Tungsten Carbide. Formed by mixing Tungsten powder with powdered Carbon, this chemical compound has an increased hardness value of 9.0 on the Mohs scale – comparable to the hardness value of diamond.

The Tungsten Carbide alloy also has an incredibly high melting point of 2200°C. Therefore, compared to Tungsten in its pure form, Tungsten Carbide is more widely used as it has the qualities of Tungsten with the added benefits of Carbon.

Application of Tungsten Carbide

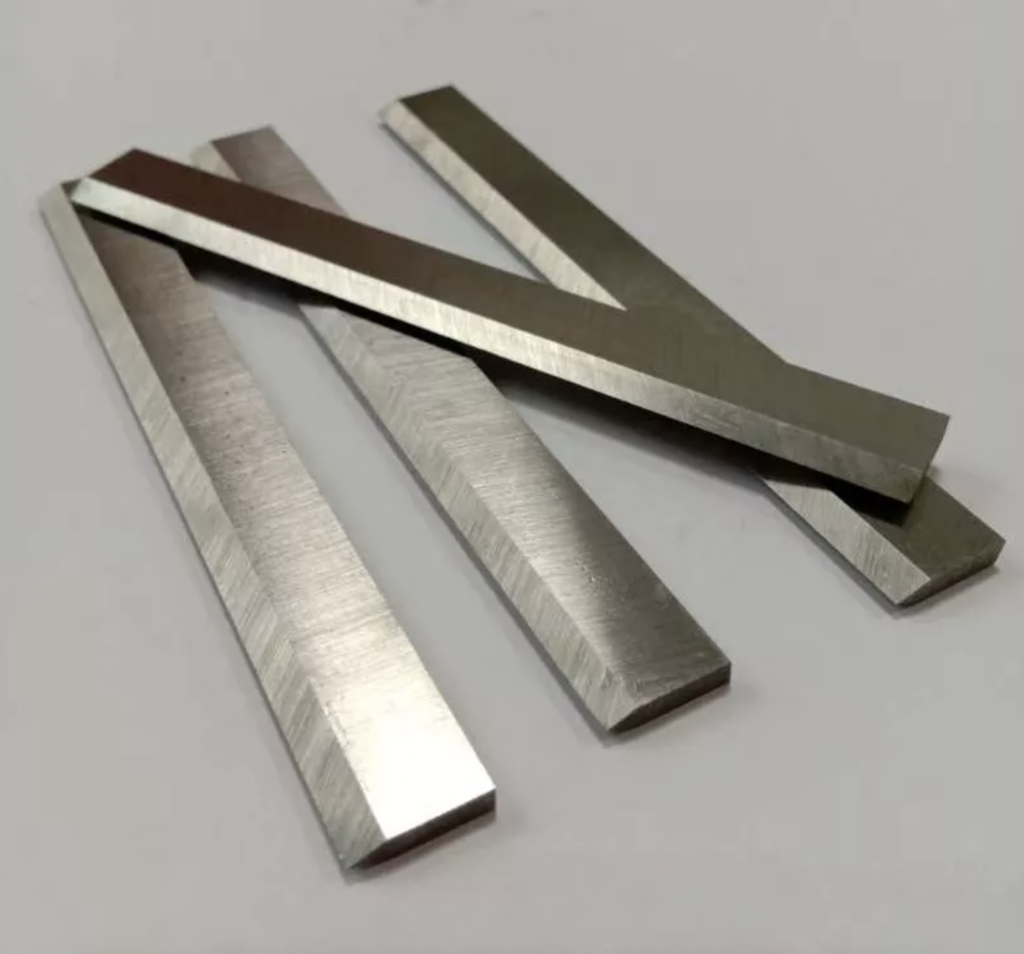

With such great heat and scratch resistance and durability, Tungsten Carbide is most commonly used in industrial cutting applications, i.e. machine knives.

Tungsten Carbide has been utilised in this industry for almost a century. Here the Tungsten Carbide is used to cut carefully controlled shapes over and over again. Tungsten Carbide has been chosen as the best, most appropriate material in this scenario. Its durability and wear-resistance allows it to cut intricate shapes repeatedly without receiving any damage.

The high heat resistance of Tungsten Carbide also makes it able to spin at high speeds for long periods of time, without overheating and causing damage. This is why Tungsten Carbide is also used in the production of wear-resistant components, for example, saw and drill tips and crushing machinery.

If you want to learn more or find out about our range of tool steel products, call (+44)114 233 5291 today to speak to a member of our team.

Tungsten Carbide Vs Steel

Commonly used for many of the same applications, Tungsten Carbide and Steel are often closely compared. There is much debate in both the machine cutting industry and the knifemaking community for which material is best.

Of course, both Tungsten Carbide and Steel have their pros and cons, so let’s take a closer look at them.

Wear Resistance

While most tool steels have incredibly high wear resistance, Tungsten Carbide does win the award for having the greatest wear resistance out of the two. This value is essentially used to describe how hard it is to remove the material through wear. This quality is essential in the machine cutting industry, meaning Tungsten Carbide wins a point here.

Toughness

If it’s toughness you’re after, then steel definitely wins. Tungsten Carbide shouldn’t be your first choice when it comes to choosing a material known for its toughness. Toughness refers to a material’s ability to withstand impacts and sustain shocks without breaking. Due to Tungsten Carbide’s density, it has a low toughness value. If toughness is an important quality for your project, you would be better off using D2 tool steel or something similar.

Maintenance Needs

The increased wear-resistance of Tungsten Carbide means that it’s rarely damaged and doesn’t require changing as often as most tool steels. This is a vital quality for the machine cutting industry. For example, if your guillotine blades need replacing regularly, your factory will experience a lot of downtime. Using Tungsten Carbide in your machine knives reduces this need and maximises profitability.

Cost

The cost of Tungsten Carbide is much higher than steel as it is more difficult to obtain. However, it ultimately depends on the situation you require the material for. Due to its longevity and wear resistance, machine knives made from Tungsten Carbide will last longer than blades made from steel, so it may be worth considering the cost of steel replacements and deciding on a material that way.

Edge Retention

Compared to tool steels, blades made from Tungsten Carbide hold their cutting edge for a dramatically longer period of time. This is also true when working at high temperatures, which may be crucial depending on your project.

Sharpening

Although Tungsten Carbide will hold its edge for much longer than steel, it is very difficult to re-sharpen carbide edges if it becomes dull. While steel may not hold its edge for as long as Tungsten Carbide, it is much easier to sharpen, increasing its longevity over time.

Choosing between Tungsten Carbide and Steel ultimately depends on what you plan to use it for and the qualities you require.

Many DIY knife makers find Tungsten Carbide too difficult to work with, as most common abrasives used on steel will not work on Carbide. Although it can hold a sharp edge well, it’s not a favourite within the knifemaking community as it is more brittle than steel.

One of the clever ways in which you can benefit from the qualities of both materials is to use a ‘Tungsten Carbide Braze’. This refers to the process of sandwiching the materials together or depositing a thin layer of Tungsten Carbide onto the sharp edge. This can also help reduce the cost of a project if you want to benefit from the physical properties of Tungsten Carbide without paying the full price.