Leading Stockholders And Suppliers Of M2 High-Speed Steel, Delivering Across The UK And Worldwide

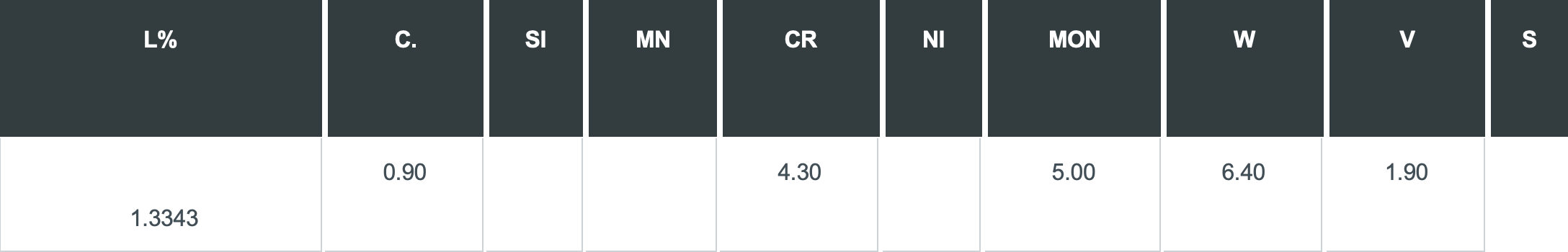

What Is M2 1.3343 High-Speed Steel?

M2 high-speed steel is the most commonly used, conventionally manufactured, medium-alloy high-speed steel and is universally applicable for tools of all kinds.

Otherwise known as 1.3343 steel, M2 can be characterised by a ≤260HB delivery condition hardness and an achievable hardness after treatment of ≤65Hrc. It is one of the most popular tungsten-molybdenum tool steels that delivers great bending strength and well-balanced toughness. As a result, it’s ideal for jobs that require strong wear resistance over time but also need a malleable metal that can be moulded into the right shape easily, such as drill bits and milling cutters.

At Sheffield Gauge Plate, we stock a range of tool steels, including M2, so there’s something for every client. When it comes to high-speed steels, our focus is on the most common grades, but we have flexible options to suit every project. Call (+44)114 233 5291 or contact us online for a more detailed chat about our stock and how we can get you the right product to suit your needs.

M2 Applications

As a popular high-speed steel, M2 is used for a range of applications, particularly cutting tools where the demand for hardness is moderate. For example, M2 is popular in the production of tools such as twist drills, milling tools, taps and saws. M2 can be sold in ground flat stock, as well as bars in various shapes, offering flexibility for manufacturers. Feel free to contact our team to learn more about the non-standard and standard sizes we supply to suit any requirement.

M2 Heat Treatment Process

Here is a rough guide to heat-treating M2 high-speed steel to achieve the superior properties it is renowned for. This process can change depending on the size of the M2 component and other external factors, but this is a general overview.

Forging M2

To forge M2 high-speed steel, you should slowly pre-heat the metal to a temperature of 850 – 900°C. After this process, the temperature needs to be increased quickly until a forging temperature of 1050 – 1150°C is reached. It’s important to note that if the temperature falls below 880 – 900°C, you must begin to reheat the steel. Finally, let the furnace cool slowly with the M2 inside it until it reaches an ambient temperature.

Annealing M2

When annealing, M2 should be heated to 850°C – 900°C at a speed of no more than 220°C per hour. The M2 component should always hold at the temperature for one hour per 25mm of thickness. At the end of the annealing process, the component’s maximum hardness should be 248 Brinell.

Stress Relieving M2

For M2 high-speed steel tools that are heavily machined or ground, stress relief is recommended. To do this, heat the component to 600°C – 700°C and soak well for around two hours. Lastly, use air to cool the high-speed steel to achieve the superior red hardness properties valued in M2 steel.

Hardening M2

M2 should be hardened in two steps; first, pre-heat the component to 450 – 500°C and then further heat the metal to 850 – 900°C. Continue heating until the final hardening temperature of 1200 – 1250°C is reached. The M2 component should not remain at the hardening temperature for too long. To finish, quench in warm oil or brine and air cool back to room temperature.

Make an enquiry

Complete our form and we'll get back to you as soon as possible.