Sheffield Gauge Plate Are M42 High-Speed Steel Stockholders And Suppliers With UK-Wide Delivery.

What Is M42 Steel?

M42 high-speed steel (HSS) is a cobalt molybdenum tool steel, sometimes known as 1.3247. The chemical composition of M42 tool steel includes 8% cobalt which delivers high hardness and superior red-hardness.

It can be heat-treated to a 68-70 HRC hardness, providing fantastic wear-resistant properties. As a result, the composition and mechanical properties of M42 steel, when applied to cutting tools, stay sharp and deliver high-production cutting applications.

M42 Steel Equivalent Grades

AISI M42, 1.3247, DIN 1.3247, DIN EN ISO 4957, HS 2-9-1-8, S500, E M42

Order by phone: (+44)114 233 5291

Order by email: sales@sgpltd.co.uk

M42 Steel Applications

M42 is regarded as the best conventionally produced high-speed steel, suited for single and multi-edged tools and wear plates. The most common applications for M42 high-speed steel include saws, knives, form tools, broaches, punches, header tooling, twist drills, taps, and thread rolling dies.

Additionally, the superb wear resistance from heat treatment and high cobalt content allows this steel to produce high-hardness alloys and nonferrous alloys. These are commonly used in power generation, oil and aerospace industries that require strength and durability.

M42 is an excellent alternative to our other tool steels due to its composition. Alternatively, if you do not require a higher hot-hardness, you can consider M2 high-speed steel, which offers toughness and ease of grinding.

To learn more about the material and discover if its components suit your application, contact us today or view our Tool Steel Application Chart.

M42 Steel Form Of Supply

Here at Sheffield Gauge Plate, we supply round, square and flat bars with UK-Wide delivery. We provide high-speed steels, such as M2 (1.3343) and M42 (13247), in dimensions manufactured on a high-forming machine (GFM forging mill).

Please complete an online form or call us at (+44)114 233 5291 with your requirements and measurements to receive your free M42 tool steel quote.

Heat Treatment For M42 Steel

Our guidance for heat-treating M42 steel is advisable. However, it’s important to note that other external factors, such as the shape and size of the supply, will impact the heating, cooling and soaking times.

Annealing M42 Steel

When annealing M42, we recommended that it is done after hot working and before re-hardening. Start by heating M42 at a maximum rate of 220°C per hour until a temperature of 850°C – 900°C. Hold for a minimum of two hours per 25 mm thickness. Then, cooling slowly in a furnace is essential to a temperature of 700°C.

Stress Relieving M42 Steel

Stress relieving M42 steel requires you to heat it to 600 °C – 700°C and soak it for two hours at temperature. Lastly, cool slowly to 500°C.

Hardening M42 Steel

To harden M42, pre-heat the steel thoroughly and evenly to 450°C – 500°C. Once pre-heated, continue to heat it again to 1050°C – 1190°C, hold and maintain that temperature and quench to around 550°C. Finally, air cool to hand warm temperature.

Please note: M42 can change depending on the type of work treated and should be hardened in a controlled furnace or rectified salt bath.

Read our article What is quenching for more information.

Tempering M42 Steel

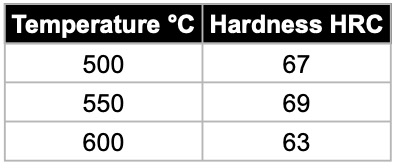

The typical tempering range of M42 tool steel is between 510°C – 595°C, and it should hold that temperature for one-hour minimum.

Triple tempering is recommended to relieve stress and increase the strength and machinability of the steel. After tempering or between tempering treatments, air cool to room temperature.

Forging M42 Steel

Forging requires the steel to be pre-heated to 650°C – 760°C and soaked. Next, heat the supply to the forging temperature of 1010°C – 1150°C, equalising before forging.

Finally, slow cooling after forging is essential.

Please note: If the temperature drops below 980°C, it must be pre-heated again before forging.

For more information or to order your M42 tool steel, call (+44)114 233 5291 or email sales@sgpltd.co.uk.

Make an enquiry

Complete our form and we'll get back to you as soon as possible.