Sheffield Gauge Plate Is A Supplier And Stockholder Of C45 Medium Carbon Steel, Delivering To The UK And Globally.

C45 Steel Description

C45 is a medium carbon steel which offers reasonable tensile properties. This steel is also commonly known as EN8 and is 080M40 steel equivalent. C45 and EN8 are both incredibly versatile due to their ability to be flame or induction-hardened. Another common name for C45 is EN 1.1191, which is the European numeric selection.

This steel provides a high strength capability on tools or equipment which are not under a lot of stress. Therefore, C45 is suitable for general-purpose axles, gears, studs and shafts. Primarily used within the automotive and mechanical engineering industry, this steel can also be applied to independent projects with its welding ability. Another feature of this material is its impressive resistance to corrosion and homogenous metallurgic structures.

C45 Tool Steel Properties

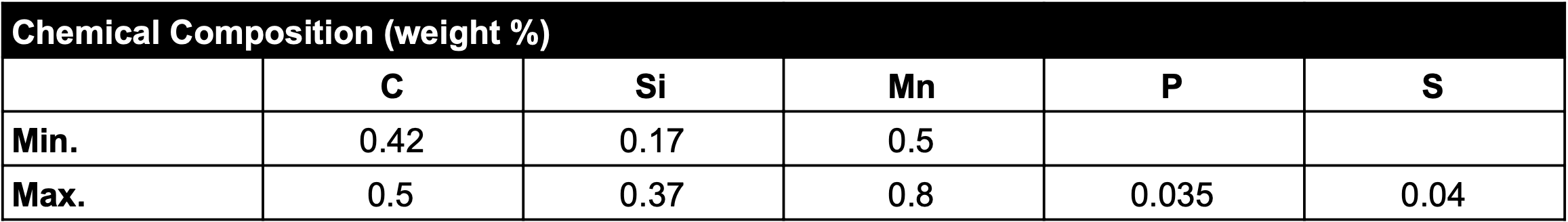

Steel, in general, is made up of iron and contains between 0.2% to 2.1% carbon. Medium carbon steel has carbon levels between 0.30% to 0.60% and manganese levels of 0.60% to 1.65%.

C45 steel is ductile and robust, containing 0.42% to 0.50% carbon and 0.50% to 0.80% manganese. The C45 chemical composition and compromise between toughness and strength promote this material as a highly functional steel with moderate wear resistance.

C45 Steel Form Of Supply

C45 is manufactured in an untreated condition and supplied in pre-machined bars. These bars are 1000mm in length with sizes of 4mm upwards and widths 20mm upwards. Sheffield Gauge Plate can also provide small squares of C45 tool steel, so please get in touch for more information.

For our complete C45 supply list, call our team of steel specialists on (+44)114 233 5291 or email us at sales@sgpltd.co.uk, and we will be happy to assist.

Application of C45 Tool steel

This medium carbon steel is an excellent substitution for steel alloy if you require a cheaper material for your project. C45 is popularly used in applications which require a stronger material than mild steel. The most common commercial applications of C45 steel are for general engineering components and automotive parts, including connecting rods, axles, spindles, studs, gears, knives, paint scrapers and bolts. In addition, this steel can be heat-treated, increasing its strength for specific applications.

Forging C45 Steel

Forging refers to the process which shapes a metal using compressive force. It is impossible to forge C45 steel under 850°С, so it is essential to heat your steel to between 1100°С to 1200°С. Pre-heating is necessary between 750°С and 800°С and once you have finished forging, cool down with air or in a furnace.

Annealing C45 Steel

In metallurgic terms, annealing is a heat treatment that changes a material’s physical properties. For example, this can make your steel easier to work with and reduce its hardness. For carbon steel, you must heat it to between 680°С-710°С ensuring it is soaked well. Once your steel reaches this temperature, allow it to cool slowly in a furnace to reduce internal stress. This process will strengthen the steel.

Hardening C45 Steel

A metalworking process to harden steel is called hardening. For example, to harden C45, you must heat it slowly to between 820°С-860°С and quench it in oil or water afterwards.

Quenching is a term used to describe the rapid cooling of a metal piece in oil, water, air or another liquid to achieve a specific material property.

Tempering C45 Steel

Tempering can increase the toughness of a particular metal, and it is used more commonly for alloy-based metals. This process will heat the metal to a critical temperature and air-cool.

Temper this medium carbon steel directly after quenching when your equipment is still warm. Then, re-heat your C45 steel to between 550°С-660°С and soak for one hour per 25mm thickness.

Welding C45 Steel

Welding is the fabrication process which connects metal. It is the process of heating the surface to an extreme temperature to melt each part together. Although welding C45 is difficult, it is possible. This steel must first be heated to between 200°С-300°С and then annealed directly after.

Please contact us for friendly and reliable advice if you would like to place an order or require technical information. Call us at (+44)114 233 5291, and a Sheffield Gauge Specialist will be happy to assist!

Frequently Asked Questions

-

What is C45 tool steel?

C45 is the steel equivalent to EN 1.1191, more commonly known as EN8 or 080m40. C45 is a medium carbon tool steel which is more commonly used for automotive and mechanical engineering components.

-

What is the HRC of C45 steel?

HRC refers to the Rockwell C scale, and the higher the number, the tougher the material. C45 steel can be hardened through various quenching and tempering treatments, finishing at an HRC of 55.

-

Is C45 steel similar to EN9 steel?

C45, also known as EN8, is very similar to EN9; however, it contains a slightly lower carbon level. For a full steel comparison, visit our blog EN8 vs EN9 and discover which steel is best for your next project.

Make an enquiry

Complete our form and we'll get back to you as soon as possible.