A2 Tool Steel Suppliers delivering to the UK and Worldwide.

A2 Tool Steel Properties

AISI A2 Tool Steel is an air-hardening, cold-work steel that belongs to the ‘A’ steel group. It features good wear resistance and is characterised by its versatility, durability and dimensional stability during heat treatments.

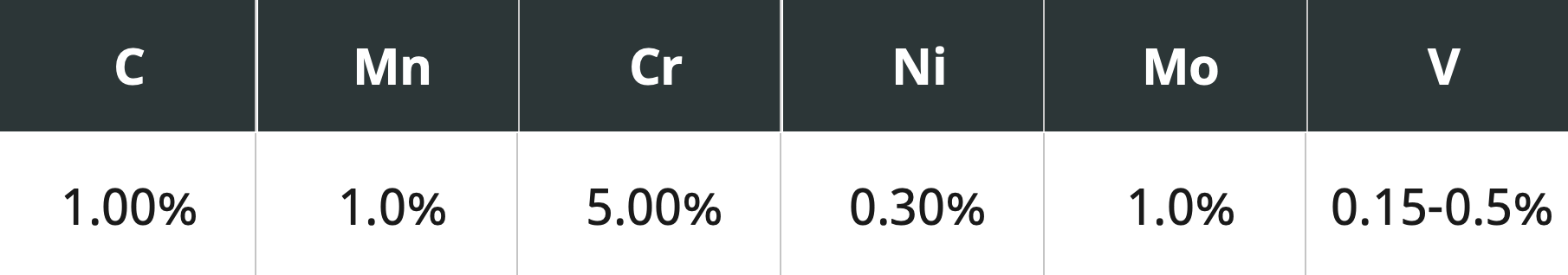

Air-hardened steels contain a higher chromium content than other steel grades, such as O1, that provide safer hardening with less distortion. Although A2 and O1 are both cold-work steels, A2 must be air-hardened, and O1 must be oil-hardened. This is a result of the higher chromium (5%) and molybdenum (1%) levels in A2.

Download our complete A2 Tool Steel Data Sheet.

Overall, A2 is an intermediate product between O1 oil-hardening steel and D2 high-carbon and high-chromium steel. Read our A2 VS O1 Tool Steel comparison article for more information on their differences and compositions.

Order by phone: (+44)114 233 5291

Order by email: sales@sgpltd.co.uk

A2 Tool Steel Equivalent Grades

AISI A2, ASTM A681, DIN EN ISO 4957, BS 4659, JIS G4404.

Applications

A2 is a popular steel, supplied and used worldwide due to its performance and machinability. The main applications include cold forging dies, hammers, shear blades, punch dies, stamping dies, coining dies and blanking tools.

In addition, A2 offers superb polishing and grinding capabilities. As a result, it is a popular steel for machine knives and cutting knives used for wood, paper and resin-bonded material.

View our Tool Steel Application Chart.

To determine if A2 is the correct tool steel grade for your next project, please contact us at (+44)114 233 5291. Our friendly team of steel experts can advise on steel suitability, pricing and delivery to ensure you find the right steel for your requirements.

Form of Supply

At Sheffield Gauge Plate, we supply A2 tool steel as flat bars, ground flat stock, sheets and diameters. A2 is customisable, so we can provide your tool steel in the necessary form and with extreme tolerance precision.

We supply all standard imperial and metric sizes, with the option to produce all non-standard sizes if we don’t already hold the stock. Additionally, we offer worldwide delivery to all orders and have previously supplied A2 steel to some of our clients in America, Australia and Canada.

Forging A2 Tool Steel

To begin, pre-heat slowly to 650°C – 700°C. Then, continue heating rapidly to 1050°C – 1100°C and avoid working below 900°C.

It’s essential to maintain proper forging temperature of 1000°C at high pressure until the metal begins to yield.

Finally, cool the steel slowly after forging to avoid cracking.

Annealing A2 Tool Steel

During the annealing process, using a controlled environment, such as a furnace, is crucial to prevent decarburisation and maintain the steel’s strength.

Heat A2 tool steel slowly until it reaches 850°C – 870°C. It should hold this temperature for a minimum of two hours before the furnace temperature is lowered to 730°C – 750°C. A2 should maintain this temperature for a further four to six hours before cooling slowly to 600°C in the furnace, followed by air cooling.

Please note: A2 is supplied in an annealed condition. Therefore, re-annealing is only necessary if you have re-hardened, re-machined or forged the steel.

Stress relieving A2 tool Steel

When working with A2 steel, it is vital to stress-relieve the material to minimise the risk of cracking or distortion during subsequent heat treatments.

Slowly heat A2 steel to 670°C – 700°C, soaking for at least two hours for every 25 mm section and cooling in a furnace.

As an extra step, you can machine-finish the steel to improve the aesthetic appearance or attain additional mechanical properties that enhance the steel’s performance.

Hardening A2 tool Steel

To harden A2 steel, pre-heat slowly to 790°C – 820°C and soak thoroughly. Then, proceed to heat the material to 950°C – 980°C, ensuring the steel is evenly heated throughout to equalise.

Once it reaches this temperature, remove it from the furnace and air quench. It’s recommended to temper the steel once it reduces to hand-warm temperature.

To learn more about hardening your steel, visit our What is quenching article.

Tempering A2 Tool Steel

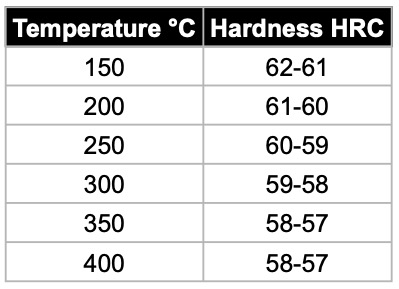

Tempering should be performed following the hardening process to increase ductility and reduce brittleness.

Heat uniformly to the required temperature, holding for one-hour minimum per every 25 mm section and air cool. A2 can be double-tempered, and it is recommended.

Repeat the process to double temper.

All information and guidance on the supply of A2 tool steel or any other tool steel grade are not guaranteed. Your evaluation of the steel should be made using our illustrative advice.

For more information or to order your A2 tool steel, call the team at (+44)114 233 5291 or email sales@sgpltd.co.uk.

Frequently Asked Questions

-

What is A2 tool steel?

A2 steel belongs to the air-hardening group of tool steels. The chromium content of A2 is 5%, which allows for excellent stability when heat treatment is performed. Due to this, it is one of the most popular tool steels in North America.

-

What Rockwell is A2 tool steel?

The final Rockwell hardness of A2 is typically around 60 - 62 HRC. However, it may be lower if heat treatment and tempering have not been performed.

-

Does A2 tool steel rust?

A2 is known to rust due to the 5% chromium content it contains. Although this does offer some corrosion resistance properties to the grade, it does not make it immune.

-

Is A2 tool steel better than O1 tool steel?

There is no right or wrong answer to this FAQ, as the most suitable choice depends entirely on the intended application. A2 provides medium wear resistance and toughness; however, O1 offers greater machinability and strength. Speak with an expert at (+44)114 233 5291 to discover the most appropriate material for your next project.

Make an enquiry

Complete our form and we'll get back to you as soon as possible.