Sheffield Gauge Plate Is The UK's Top 420 Tool Steel Stockholder And Supplier, Delivering To The UK And Globally

420 Stainless Steel Description And Properties

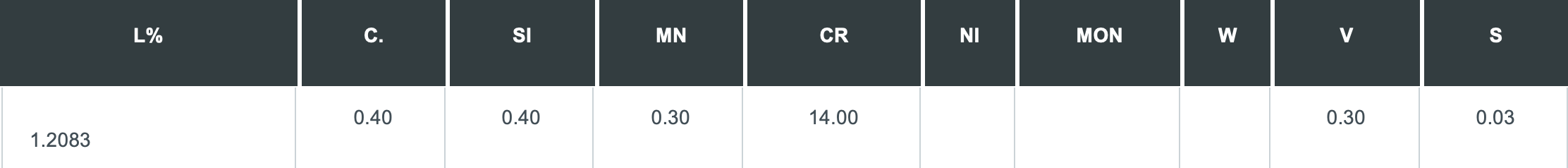

420 tool steel (1.2083) is a chrome-alloy, wear and corrosion-resistant plastic mould steel which, when fully hardened, is considered to be the hardest of the martensitic family of stainless steels. This tool steel can be characterised by its high chromium content and resistance to corrosion and acid, especially when hardened, tempered, and polished. Like all martensitic stainless steels, 420 has strong magnetic properties, which, combined with its high carbon content, make it ideal for a range of applications.

Due to these fantastic properties, 420 (1.2083) plastic mould steel is an excellent choice for industries that have high hygiene standards, such as the medical and optical markets. If you need to forge 420 tool steel, then you should heat it slowly and uniformly until it reaches a temperature of 1000°C. Afterwards, take the steel and cool it slowly in a furnace.

Hardening 420 involves preheating the steel to 600-700°C until it is heated. Then, continue to heat until a temperature of 980-1050°C. It is essential to protect 420 from decarburisation, which can be done by using a salt bath, atmosphere furnace or vacuum. Finally, air cool or quench in oil to achieve a higher hardness and bring out all the other properties of this stainless steel grade, including its durability, corrosion resistance and more. The result is a durable, polished martensitic stainless steel with strong corrosion resistance properties that can last for many years and retain its bright appearance.

420 Tool Steel Forms

420 stainless steel comes in a range of forms, including bars, plates and ground flat stock. Each option comes in various shapes, so there’s something for every application.

Sheffield Gauge Plate provides 420 stainless steel in plate, flat bar, round bar, and diameter steel tube forms. Ground flat stock can also be supplied in non-standard and standard sizes, no matter the order quantity. As such, we’re the only tool steel supplier you need for any project involving 420 stainless steel.

420 Stainless Steel Applications

420 is perfect for plastic moulds and different inserts because of its mechanical properties, which allow it to be polished to a high shine. Thanks to its outstanding corrosion resistance and air-hardening characteristics, 420 stainless steel is used throughout a range of industries, including manufacturing, optical and medical.

In these markets and others, 420 tool steel is popular for making cutlery, surgical instruments, knife blades, machine knives, hand tools, shear blades and scissors. Grade 420 coated welding rods are also recommended for high-strength joints, which are used in food processing and other manufacturing sectors.

The higher carbon content of 420 stainless steel means it’s ideal for large-scale machine parts, as it can absorb a lot of pressure without cracking. However, its high carbon content means 420 is not commonly welded.

Fortunately, when hot working is undertaken to achieve annealed hardness, 420 steel exhibits good corrosion hardness and is easily moulded into the right shape. As a result, 420 tool steel can be a great higher carbon version of many other common steel products available. If you have a tooling project that you think grade 420 would be suitable for, contact us today to discuss your options.

420 Heat Treatment Options

To get the best from its physical properties and achieve the highest hardness possible, grade 420 tool steel can be heat-treated by annealing and hardening. For annealing, the steel is heated at between 840-900 °C, with a focus on uniform heating throughout the metal. Then, it goes through a process of slow furnace cooling at 600 °C, followed by air cooling.

For the hardening process, the 420 tool steel is heated to between 980 and 1035°C before undergoing either air or oil quenching. Oil quenching is the preferred quenching medium for machine tool applications and heavy metal sections. Tempering at a relevant tempering temperature, in this case, between 150 and 370°C, can bring out the best of 420’s mechanical properties, but your heat treatment provider should be careful to avoid over-tempering. When hot work with 420 tool steel is done right, the result is a smooth surface finish and a hardened condition that is ideal for a range of uses.

On the other hand, 420 stainless steel can handle only minor cold work and isn’t well-suited to sub-zero temperatures. As such, if you want a tool steel for cold working, grade 420 is not the best choice.

Thankfully, Sheffield Gauge Plate offers a wide range of other tool steel products that are better suited to cold working, so you can find the perfect steel for any project.

420 Ground Flat Stock

Ground flat stock, or gauge plate, is ideal for large construction or manufacturing projects. With its high hardness and good ductility in its annealed condition, grade 420 can be ideal for plastic mould steel tools and blades. The material can then be treated at elevated temperatures and moulded through the heat treatment process to get the most from its mechanical properties, including the best corrosion resistance and tensile strength.

As a leading 420 tool steel supplier, Sheffield Gauge Plate has products available to provide ground flat stock promptly to meet any deadline. Our flat ground stock is supplied in both metric and imperial measurements, and we offer a range of lengths and thicknesses. Additionally, if you require a supplier that can provide non-standard sizes, you’re in the right place. We can also offer full guidance on the best tool steels for your next job.

Contact us today on (+44)114 233 5291 to learn more about our product range and hire work facilities or to place an order for 420 tool steel.

420 Steel Frequently Asked Questions

-

Is 420 A Good Blade Steel?

420 steel is often used for blades, however, because it has a lower carbon content than other steel products, it can make for a softer blade that doesn't hold an edge as well as other steel grades. As such, it is often used for low-impact blades, such as cutlery.

-

Does 420 Steel Rust?

420 has corrosion resistant properties, meaning that it is less likely to rust than other steel grades. That's why 420 is often used in the medical industry.

Make an enquiry

Complete our form and we'll get back to you as soon as possible.