Sheffield Gauge Plate is a Supplier and Stockholder of EN8 Steel, Delivering To The UK And Globally.

EN8 Steel Description

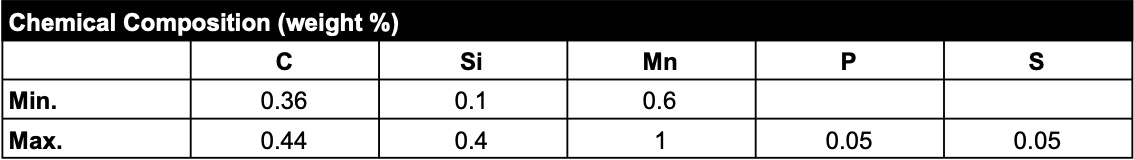

EN8 (080M40), commonly known as C45, is unalloyed medium-strength carbon steel. Offering intermediate strength with quality tensile properties, the use of EN8 steel is popular for its mechanical and automotive purposes. In addition, EN8 steel provides good resistance to corrosion and is an ideal material for loading applications. In other countries, EN8 is referred to as ‘axle steel’, which is one of the main applications for this material.

EN8 Steel form of supply

Our EN8 engineering steel bars come in an untreated condition, so you have the flexibility to harden the steel through various induction processes. Once EN8 steel is in this heat-treated form, it possesses homogenous metallurgical structures. This provides more accurate machining properties for your desired shape.

Sheffield Gauge Plate supplies steel EN8 in pre machined bars of 1000mm lengths with sizes ranging from 4mm upwards in thickness to 20mm upwards in width. Small squares are also available.

Please get in touch and speak with our steel experts for more information on sizing and pricing.

Application of EN8 Steel

EN8 carbon steel is used for tools and general engineering components such as automotive parts, connecting rods, bolts, axles, spindles and studs. It is favoured in applications that need superior mechanical properties than mild steel whilst being cheaper than stainless steel or steel alloy. It also provides a stronger strength level than mild steel, achieved during the thermo-mechanical rolling process.

Forging EN8 Steel

Carefully preheat the EN8 material and raise the temperature to 1050°C (we do not recommend forging below 850°C).

Once you have finished forging, allow the EN8 steel to cool slowly, ideally in a furnace.

Annealing EN8 Steel

Heat the EN8 steel slowly to 680-710°C and soak well. Once EN8 reaches this temperature, cool the steel slowly in a furnace to remove internal stresses and toughen the steel.

Hardening EN8 Steel

Heat your EN8 steel slowly until it reaches between 820-860°C.

Quenching the steel in oil or water after it reaches this temperature will harden the steel.

Tempering EN8 Steel

EN8 can be tempered to adapt the steel’s properties to your desired application. Tempering occurs between 550-660°C, heating approximately every 1 hour per 25 mm of the total thickness (2 hours minimum). After the steel has reached temperature, cool it in oil or water.

We recommended tempering EN8 immediately after quenching to toughen the steel by reducing brittleness and internal stresses.

Welding EN8 Steel

Modern EN8 steel contains less carbon than it once did; therefore, it is possible to weld a strong joint.

If you are welding in pieces of up to 18mm in thickness, you do not need to preheat the steel. However, if you are welding EN8 over 18mm in thickness, we recommend preheating the steel to 100°C to prevent cracking.

Please follow the annealing instructions after welding to prevent the steel from breaking.

Sheffield Gauge Plate are EN8 steel suppliers for UK and worldwide deliveries. For further guidance on EN8 steel, we recommend you contact a member of our team who can assist you with your query. Call us on (+44)114 233 5291 or email us at: sales@sgpltd.co.uk.

Frequently Asked Questions

-

What is EN8 Medium Carbon Steel?

EN8 is unalloyed medium carbon steel and is equivalent to the Steel Grade specification of BS 970 1955 or 080M40. It is suitable for general engineering purposes and tools as it has a more robust strength level in comparison to regular mild steel.

-

What is the hardness of EN8 steel?

EN8 Steel can be surface hardened through induction processes and reach a hardness state of 50-55 HRC.

-

What are the differences between en8 and en9 steel?

EN8 and EN9 steel are both very similar; however, EN9 contains a slightly higher carbon level, resulting in higher yield strength. To find out more, visit our article EN8 vs EN9 for a comparison of these two materials to understand which is the best option for your next steel project.

Make an enquiry

Complete our form and we'll get back to you as soon as possible.