Sheffield Gauge Plate Are O1 Tool Steel Suppliers And Stockholders. Delivering O1 Steel Grade To The UK And Worldwide.

O1 Tool Steel Properties

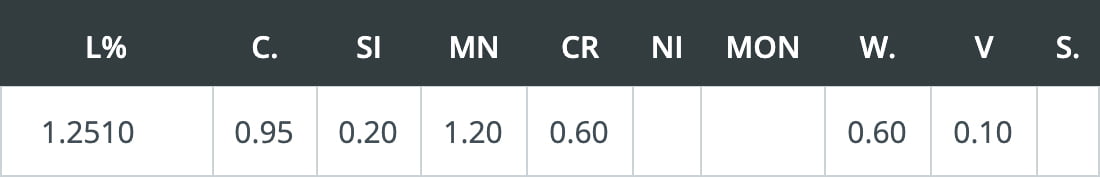

The tool steel material O1 is the most popular wear-resistance tool steel grade worldwide. It is often referred to as 01 tool steel and 1.2510 steel.

Tool steel O1 is an excellent grade of steel that has an increased Cr content and has undergone an oil hardening process. As a result, O1 tool steel is perfect for general use because it is more wear and temper resistant with impressive dimensional stability.

Overall, material 1.2510 is chromium, tungsten and vanadium steel and is one of the most commonly used oil-hardening steels worldwide.

O1 tool steel form of supply

Sheffield Gauge Plate is the company of choice when choosing your tool steel grade. We offer O1 and different materials in various forms, such as sheet, plate, flat bar and flat ground stock. Diameters are less popular, but we can still supply the required lengths in single or multiple-cut orders.

Our experienced team have been in the industry for many years, so call (+44)114 233 5291 today for professional advice or to buy O1 tool steel.

Application

Due to O1 tool steel’s wear resistance, it is used for many different applications. These applications include thread gauges, plug gauges, press tools, cutting tools, woodworking tools, broaches, cams and collets. In addition, it features a fine grain which sharpens well. Therefore, O1 is also commonly used for industrial machine knives, knife blades and shear knives.

O1 Ground Flat Stock

As O1 tool steel suppliers, we can supply ground flat stock in 1.2510 tool steel grades. In addition, O1 tool steel materials are available in various metric and imperial measurements, widths and thicknesses, unique to your requirements and applications.

So, if you require an O1 ground flat stock supplier that offers non-standard sizes and lengths, you’re in the right place. Contact our team today to learn more about how we can help with your O1 ground flat stock search.

O1 steel heat treatment

Throughout our years of supplying ground flat stock and gauge plate, we often get asked about the process of changing the chemical composition of our supplied steel. Our tool steels are generally provided in O1, so we’ve compiled this helpful guide for you to refer to if you plan to perform heat treatments to your supplied O1 steel grade.

Annealing

All our wear-resistance O1 stock is supplied in an annealed format, making annealing unnecessary if you require heat treatment. However, there are cases where you may want to re-anneal, such as when a toolmaker has forged the steel.

Start by heating the product uniformly until 780° – 800° C. Once you have reached this temperature, hold the steel for around one hour. Next, bring the temperature back down slowly in a furnace and do not exceed a rate of 25° C per hour for the first 200° C. You can use a faster cooling rate once you have brought your O1 grade back to 200° C.

Stress relieving

Stress-relieving is a standard process used for heat treatment; however, when carrying out O1 tool steel heat treatments, it is only necessary if your product is heavily machined and subject to cold work.

If you require stress relief to your supplied O1, heat it slowly until 600° – 625° C. Once the grade has reached that temperature, hold it for approximately 1 hour and then proceed to air harden.

Hardening O1 Tool Steel

When hardening your steel grade, you have two standard options; the direct and martempering methods. Hardening your delivered O1 may be necessary if you require the finished product to have mechanical properties suitable for the final operation.

If following the direct method, heat the steel to the hardening temperature of 790° C – 810° C. Depending on the size you have been supplied with, the recommended temperature may differ. In addition, if your O1 section is extensive, we recommend preheating to 650° C.

Once you have reached the temperature, proceed to “quench“, oil harden or water harden.

A less common O1 tool steel hardening method is martempering. The martempering process is only relevant for thin, thick sections with several holes or corners. The difference between direct hardening and martempering is that a salt bath quenching facility is used, which helps to reduce distortion.

To perform martempering on your supplied O1, heat the piece to the hardening temperature used in the direct method. Then, it can be quenched in oil using your salt solution, which should sit at approximately 200° – 210° C. Once equalisation has been performed, and you have held in the salt bath for a maximum of 10 minutes, remove, air cool to 80° C – 100° C and immediately temper.

Tempering

Heat treatment of O1 tool steel requires tempering to remove any excess stress introduced during the hardening process. If possible, tempering should be performed while your O1 grade of steel is at the tempering temperature of 80° C – 100° C. However, this temperature can change depending on the final output of your product application and the environment you will use it.

To temper, soak for around one hour and use an air-circulating furnace, if possible.

For more information or to order your O1 tool steel, call (+44)114 233 5291 or email sales@sgpltd.co.uk.

Frequently Asked Questions

-

What is O1 tool steel?

O1 tool steel belongs to the O series group of tool steels. This series refers to steels that have been quenched by oil. O1, often referred to as 1.2510 steel, is a popular wear-resistance cold work steel that can be hardened to 66 HRC.

-

What is the hardness of O1 tool steel?

O1 can reach a hardened state of 66 HRC when a heat treatment is performed. This high hardness threshold has made the steel grade a popular choice for all types of industrial tooling.

-

Is O1 tool steel high carbon?

The typical chemical composition for O1 is 0.95% of carbon. Therefore, this amount of carbon would be classified as high carbon content, which gives it strong wear resistance properties.

-

Is O1 tool steel better than D2 tool steel?

That entirely depends on what you intend to use it for. To compare the two more closely, visit our helpful article O1 Vs D2 Tool Steel to learn more.

-

Which is the best tool steel - A2 or O1?

Ultimately, it depends on the intended use and application of the steel, as they each have differing properties. Visit our article A2 Vs O1 Tool Steel for a comparison of the two.

Make an enquiry

Complete our form and we'll get back to you as soon as possible.